Transmission Issues

1942 Pattern 13

C60S

Transmission Update after 5 more years of running the transmission

lost a tooth in the lower cluster. See 3

Ton Transmission for information on searching for parts and repair.

Recently I posted the following thread to the MLU Forum

C60S Transmission Question

--------------------------------------------------------------------------------

I have notice a new vibration or catch in the transmission on my C60 (which

I just installed a new engine). The problem only occurs during deceleration

in 3rd gear on steep hills. It takes the form of a intermittent catch felt through

the gear shift lever. As anybody else noticed a similar occurrence, if so did

you discover a cause.

When I had the transmission out I did disassemble it to check for wear (it

has been 18 years since the truck was restored) there was no metal chips in

the case I strained the gear oil and ran it through fine filter with strong

magnet to see if there was an unusual amount of metal particles which there

were not. The only part showing wear was the pilot bearing area of the main

shaft. I'm wondering if it is just bearing chatter on the pilot bearing. See

picture.

I sort of expect the response - of course that is the problem, I'm already

looking for new main shaft and bearing, but I looking for input so I can fix

it once.

__________________

Phil Waterman

#2 Yesterday, 11:59

cletrac

David Pope Join Date: Jul 2003

--------------------------------------------------------------------------------

Phil, the only time you get any movement in the pilot bearing is when the clutch

is pressed so that's not your problem. The problem would have to lie either

with the 3rd gear on the main shaft or in the cluster gear bearings or the center

bearings on the main shaft.

__________________

#3 Yesterday, 12:47

Phil Waterman

Terminology Difference

--------------------------------------------------------------------------------

Quote:

Originally Posted by cletrac

Phil, the only time you get any movement in the pilot bearing is when the clutch

is pressed so that's not your problem. The problem would have to lie either

with the 3rd gear on the main shaft or in the cluster gear bearings or the center

bearings on the main shaft.

Hi David

Thanks for the response, my picture choice was poor resulting in a difference

in part terminology, I was referring to the Pilot Bearing 4.352 the picture

I posted is unclear it is of the Main Shaft 4.403 and not the Main Drive Gear

4.351. (see exploded view picture) Good point though the I did replace the pilot

bearing in the flywheel of the new engine so that it would mate correctly with

the original transmission.

The pilot bearing on the main shaft is turning in all gears accept 4th, which

adds to the confusion because I only have noticed the "catch" or single

chatter in 3rd gear when going down fairly steep grades 6-8% (steep for on road).

Attached Thumbnails

__________________

Phil Waterman

#4 Yesterday, 14:12

Alex Blair

Registered User Join Date: Feb 2003

Location: Ottawa ,Canada

Posts: 1,931

Wear...

--------------------------------------------------------------------------------

Quote:

Originally Posted by cletrac

Phil, the only time you get any movement in the pilot bearing is when the clutch

is pressed so that's not your problem. The problem would have to lie either

with the 3rd gear on the main shaft or in the cluster gear bearings or the center

bearings on the main shaft.

Hi Phil..

I agree with David..some good close up's of third gear and the cluster may tell

the story better..sounds like wear on the gear faces..straight cut gears will

show this wear and are more susceptible to this than angular cut gears,although

all gears wear..prolonged usage of third gear would would induce wear that would

only show on those gear faces..

And unfortunately the wear is can not be adjusted ,as shimming the crown and

pinion to adjust for proper load clearances..

But it is measurable..put in the old bearings and reassemble the transmission..

Then turn the transmission slowly by hand and feed a length of plastigage through

the teeth of third gear...record your clearances..

Then replace the bearings and do the same thing and the difference in clearances

should be measurable..If there is no difference it will be the gears..

The consistency of the clearances,which will show up on the plasticgage will

also tell you if a shaft is bent or a gear is warped

Enjoy..

__________________

Alex Blair

--------------------------------------------------------------------------------

Last edited by Alex Blair : Yesterday at 14:16. Reason: Left out a line..

Alex Blair

--------------------------------------------------------------------------------

Or wear on the splines in the bore of the third sliding gear and/or on the

splines on the splines on the mainshaft in that area. I see that the reflection

on the mainshaft appears different in that area of the spline. This will cause

the gear to cant over or twist and decrease clearances, thus binding up, or

else radial backlash will cause the crown of one gear to mesh higher up the

face of another gear rather than centrally in the valley. Is there any signs

of galling on the faces of the teeth?.

__________________

This thread is useless without Pictures!

I totally agree with Tony this thread without good pictures is useless

To post pictures large enough to see wear on the gear assemblies I brought

the thread pictures over to this my website so not to use MLU bandwidth unnecessarily.

Look to the right of the pictures for notes on the pictures

|

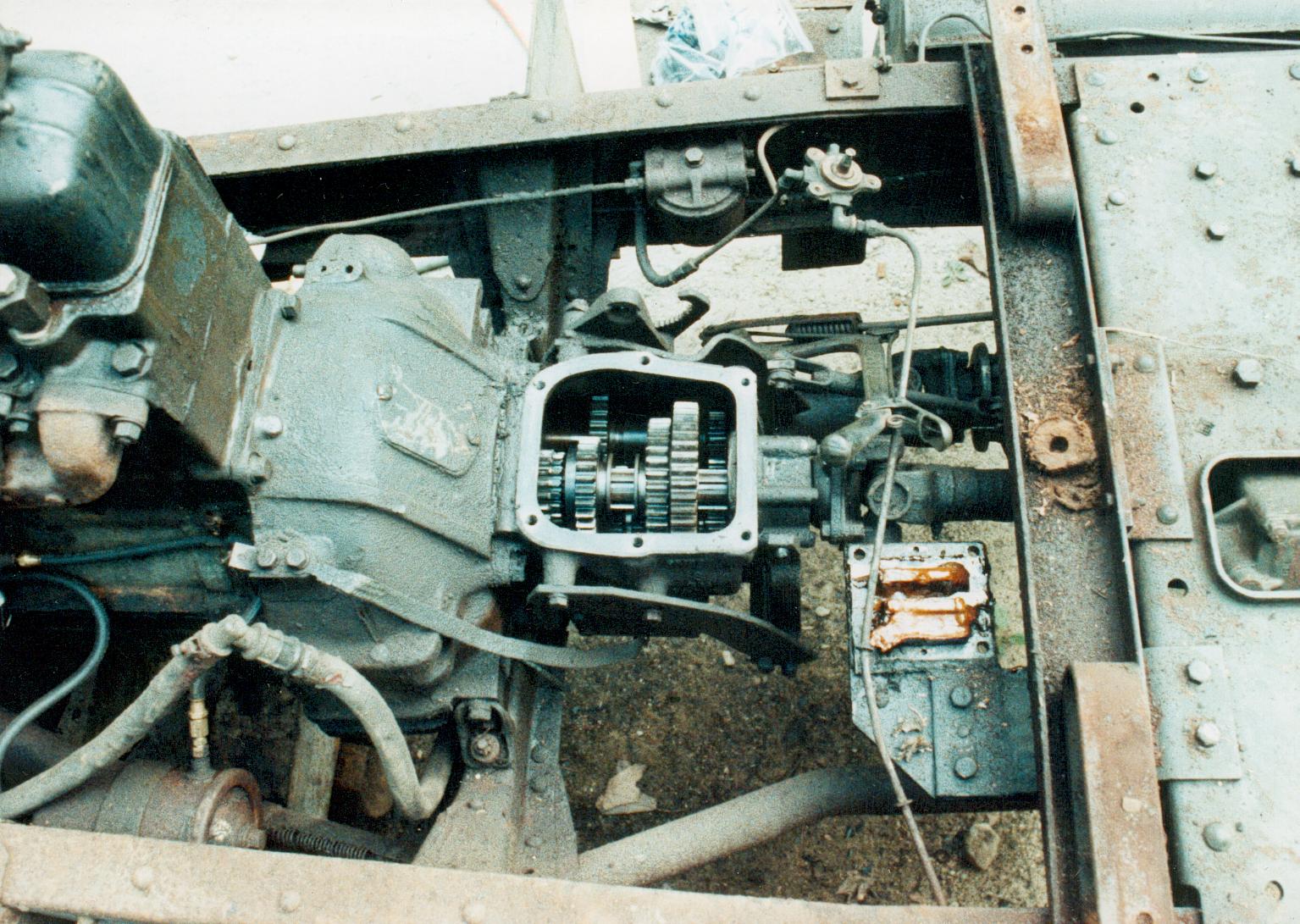

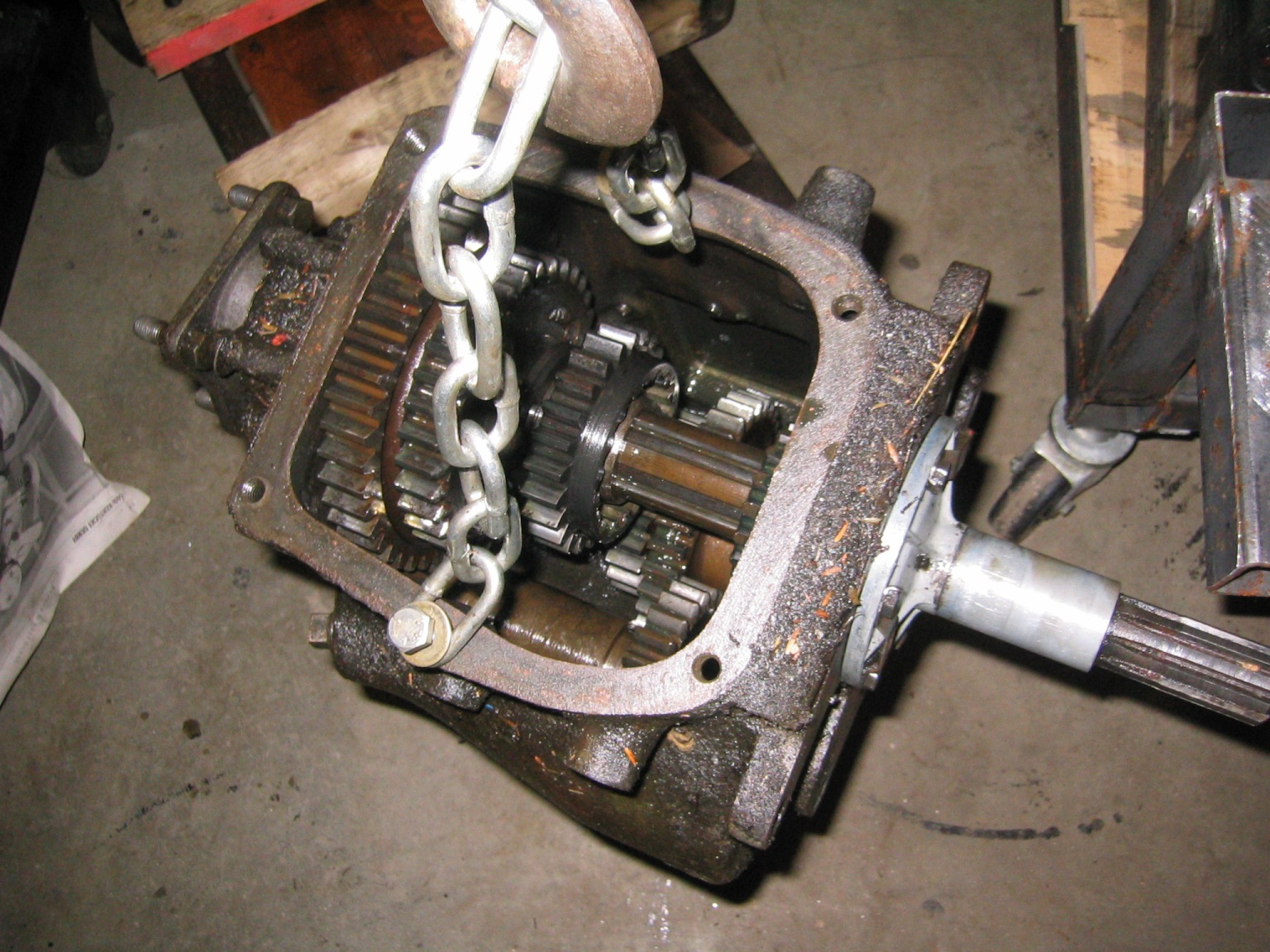

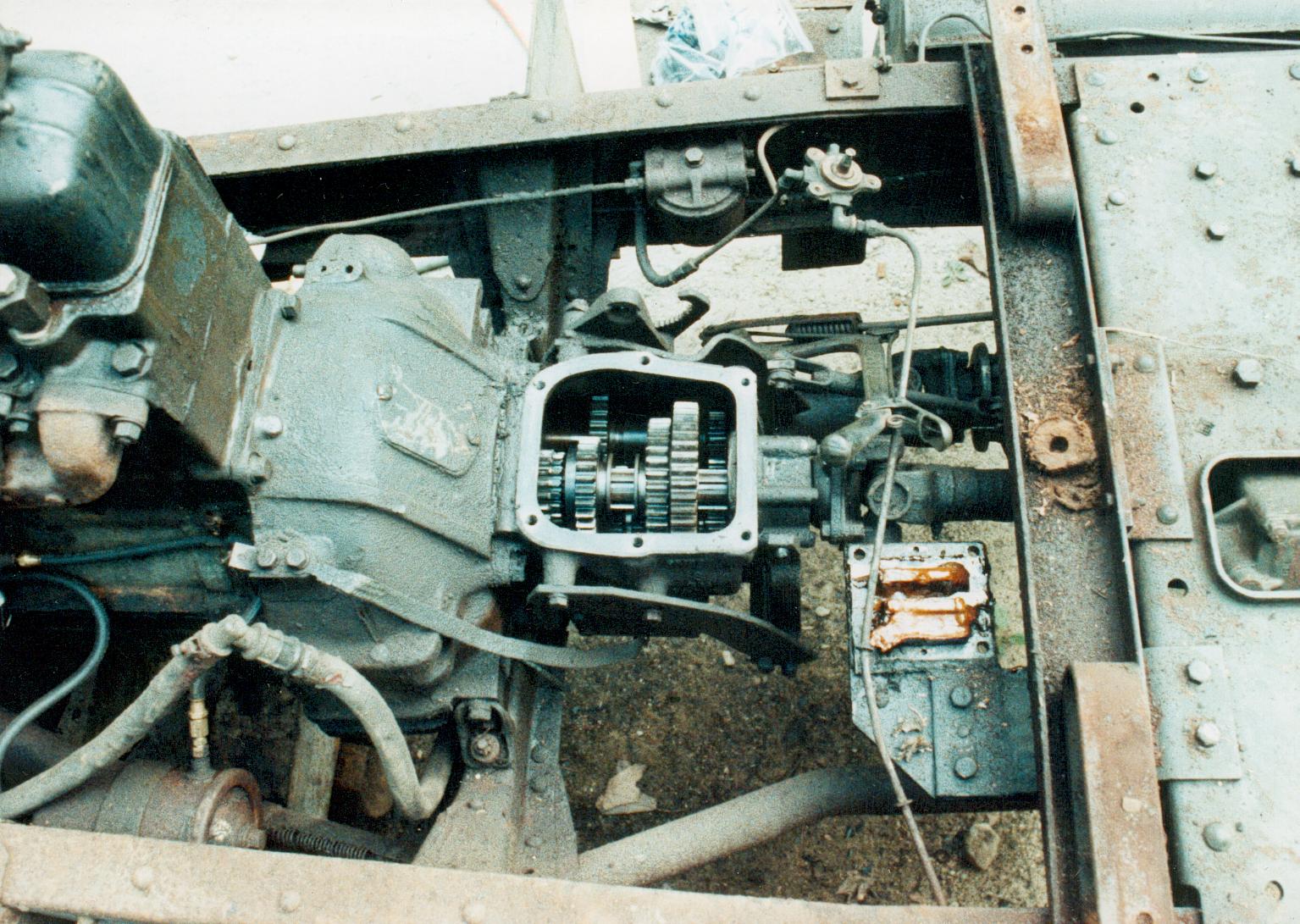

This pictures shows the rigging I use to remove the transmission form

the truck. As I work alone I have to modify the way that you might use

if you were working in a normal shop.

I have a steel box tube cut to fit between the rear of the cab and the

windshield frame. This allows me by removing the floor plate over top

the transmission to lower the entire transmission out through the bottom.

This is also useful in servicing the clutch as you can remove the clutch

without taking out the engine.

|

|

Here you see the transmission lowered to the

floor. Cardboard is just to keep trash from falling into the transmission

during the process. |

|

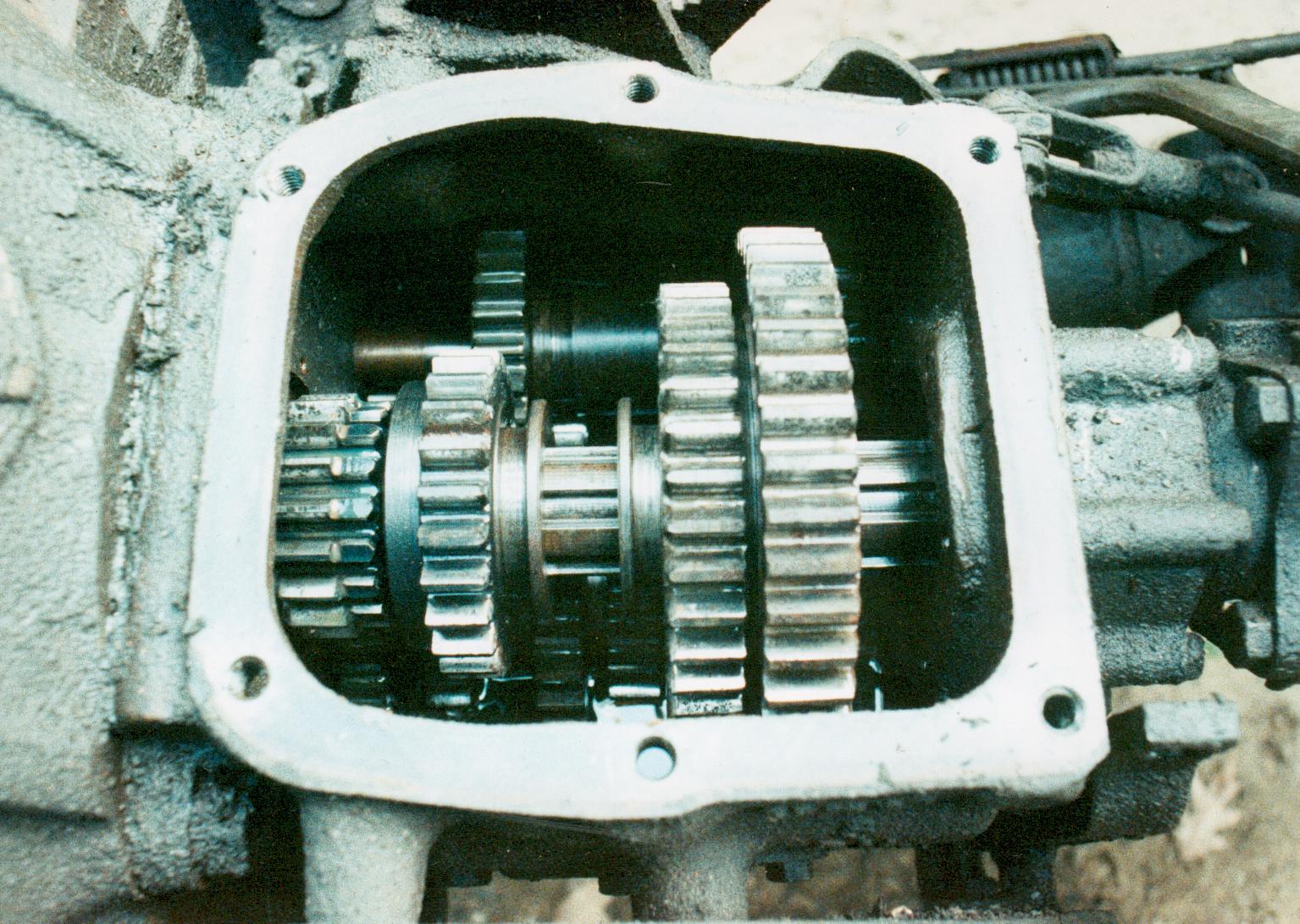

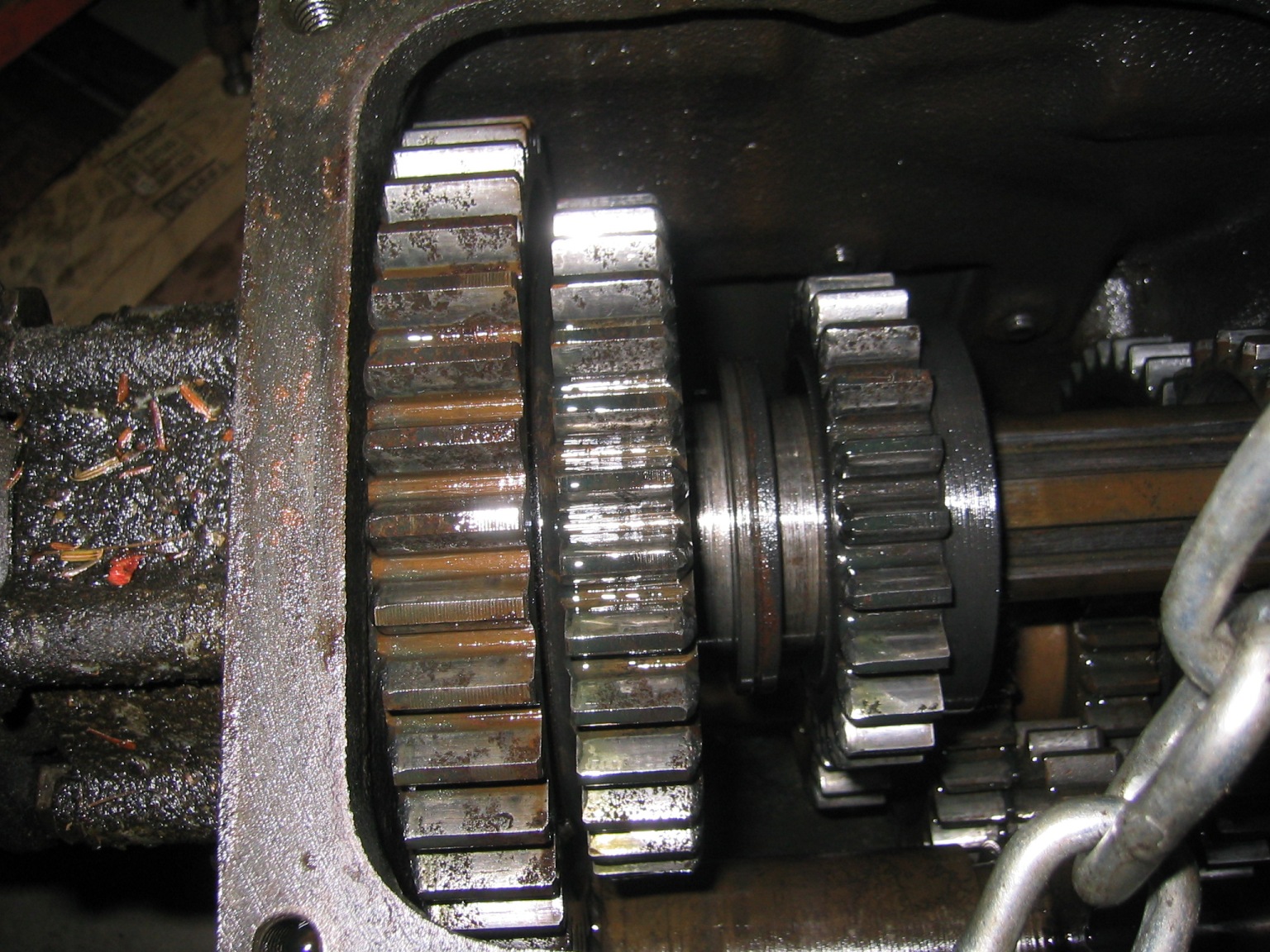

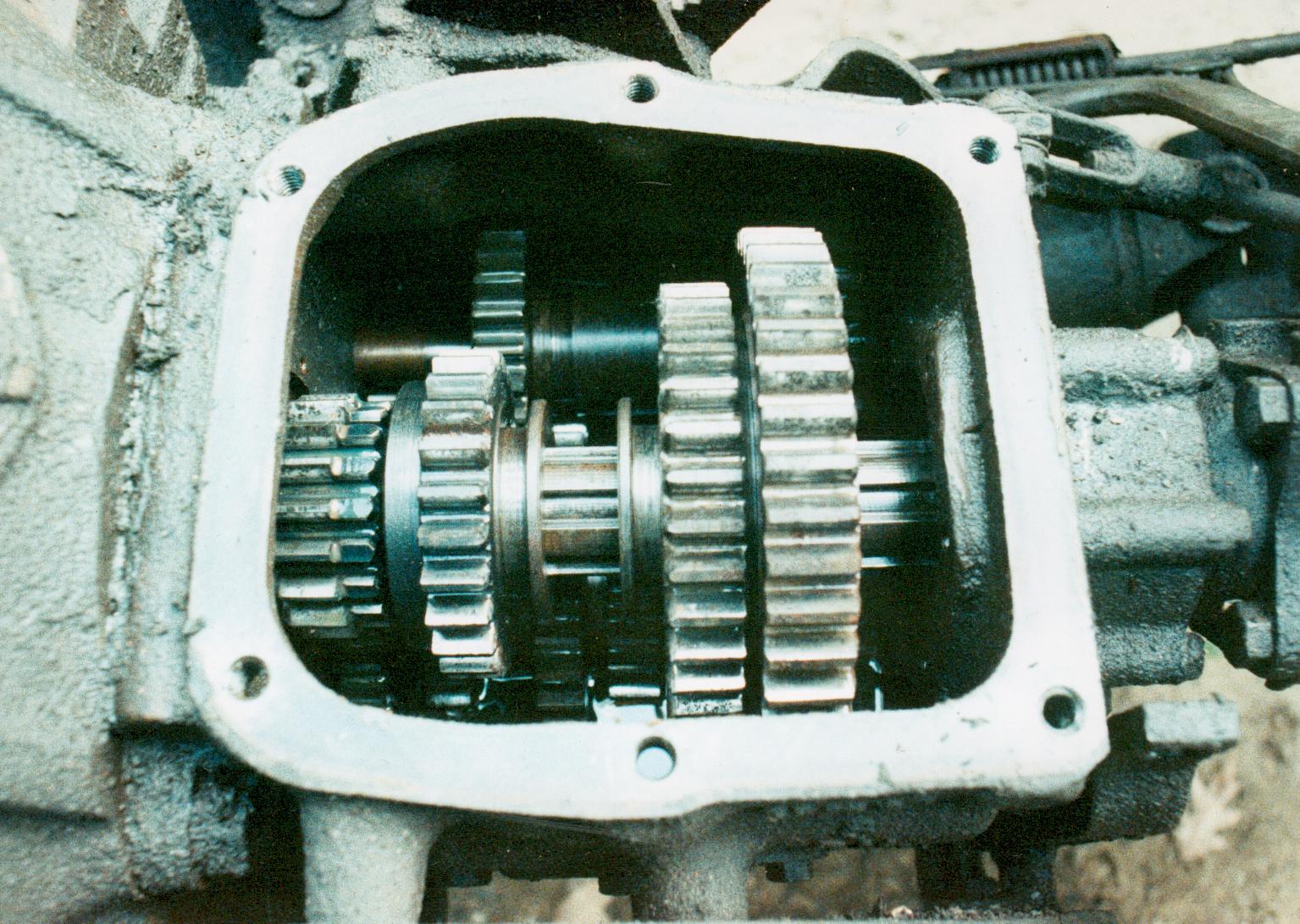

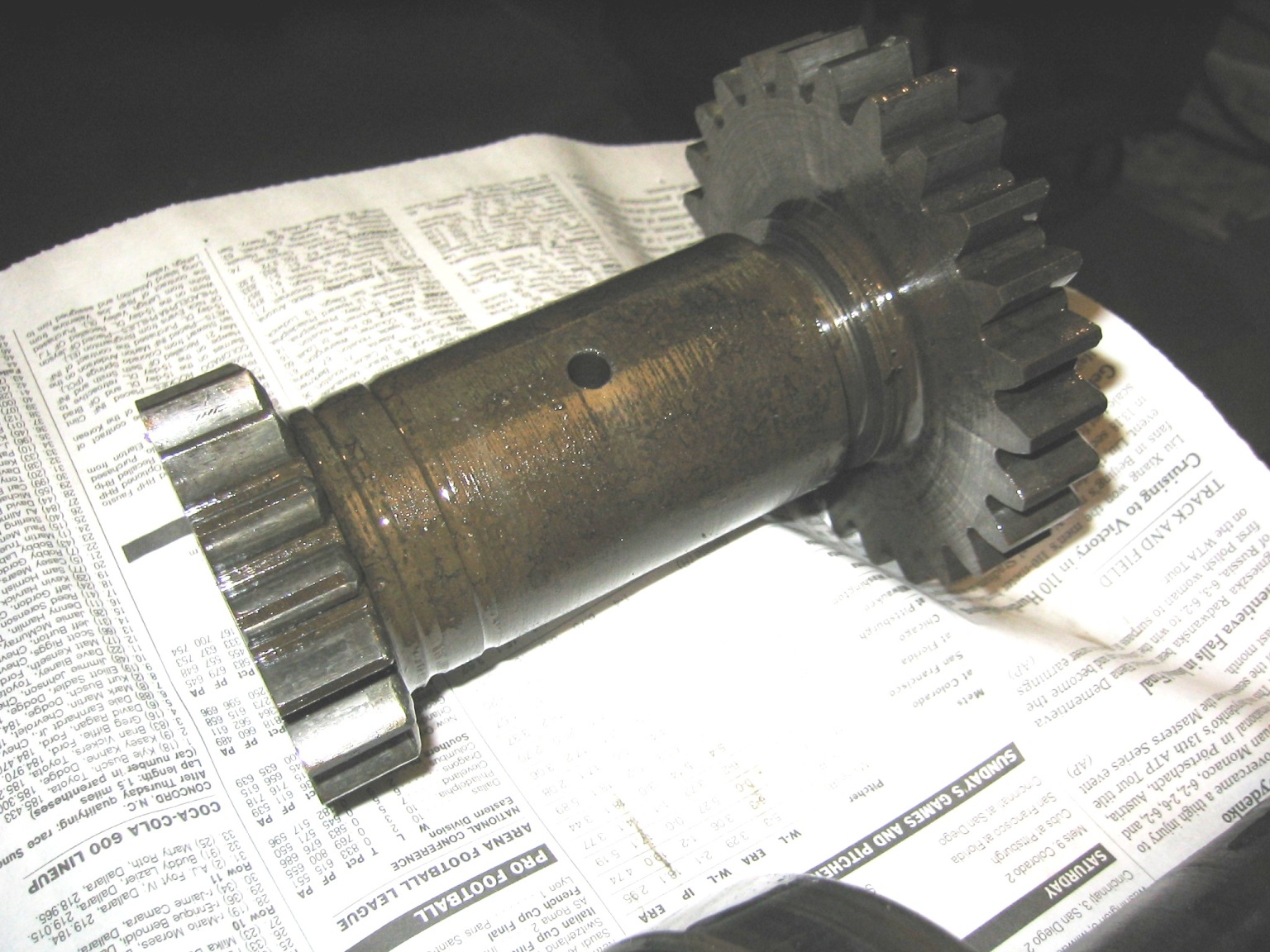

This is the picture 2008 shows the condition of the gears. First thing

to note is the rust marks on the gears. This CMP like many others had

water in the transmission when it was first restored in 1990. The picture

below shows the condition of the transmission in 1990.

Despite the rust damage the transmission has operated without problems

for 12,000 miles.

When I drained the transmission I ran it through a coffee filter with

a strong magnet to attract metal particle, not much showed up and there

were no steel bits.

Note rear of transmission is to the left

|

|

Picture taken 1990 shows water damage at that time. At that time the

transmission was completely disassemble and all the gear faces were buffed

with a mild abrasive to remove as much of the rust as possible, but with

out trying to grind out any of the pitting.

Note rear of transmission is to the right

|

|

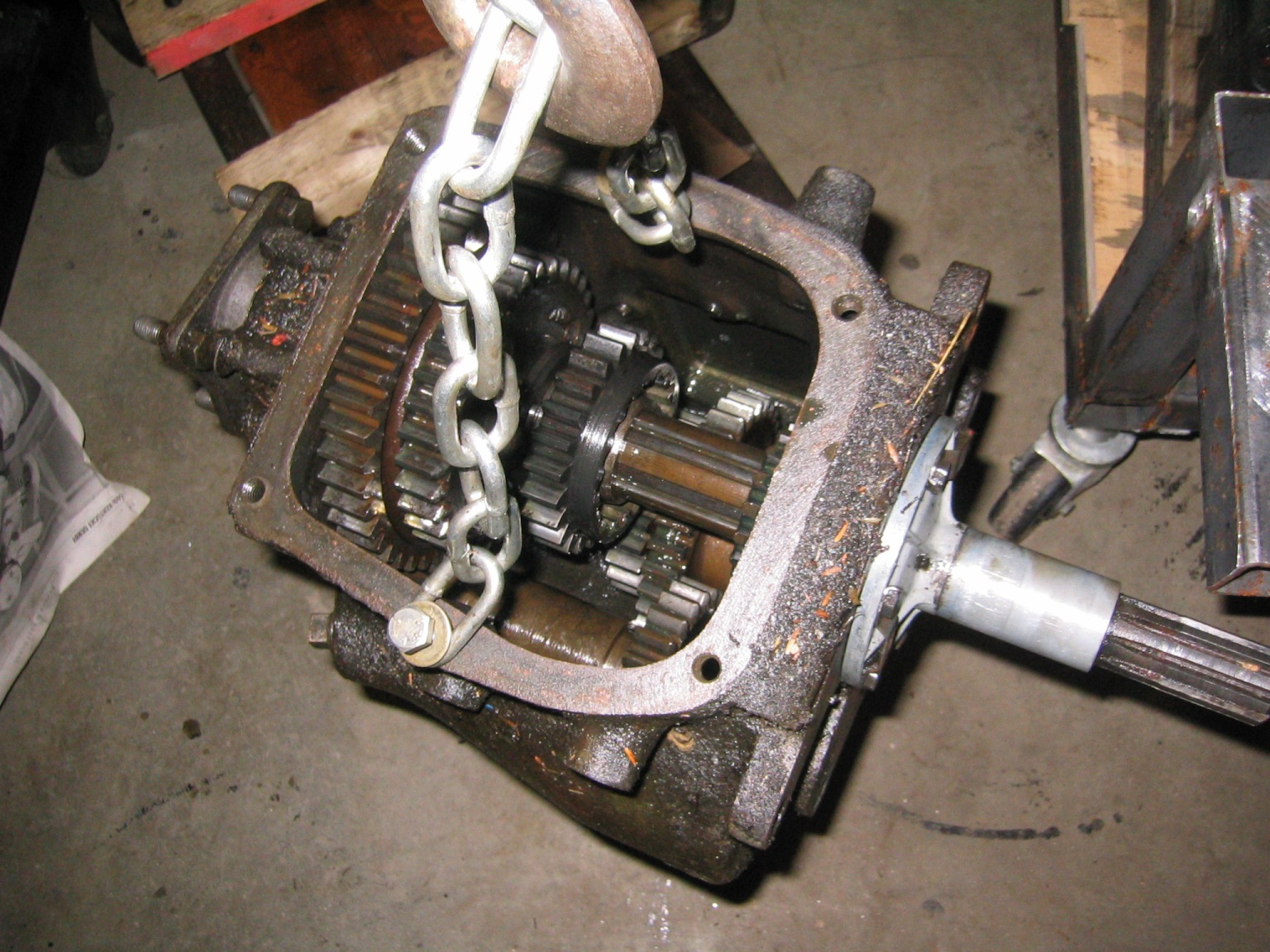

1990 In this picture you can see that the transfer

case shift tower shows evidence of water having gotten in. |

|

2008 |

|

2008 |

|

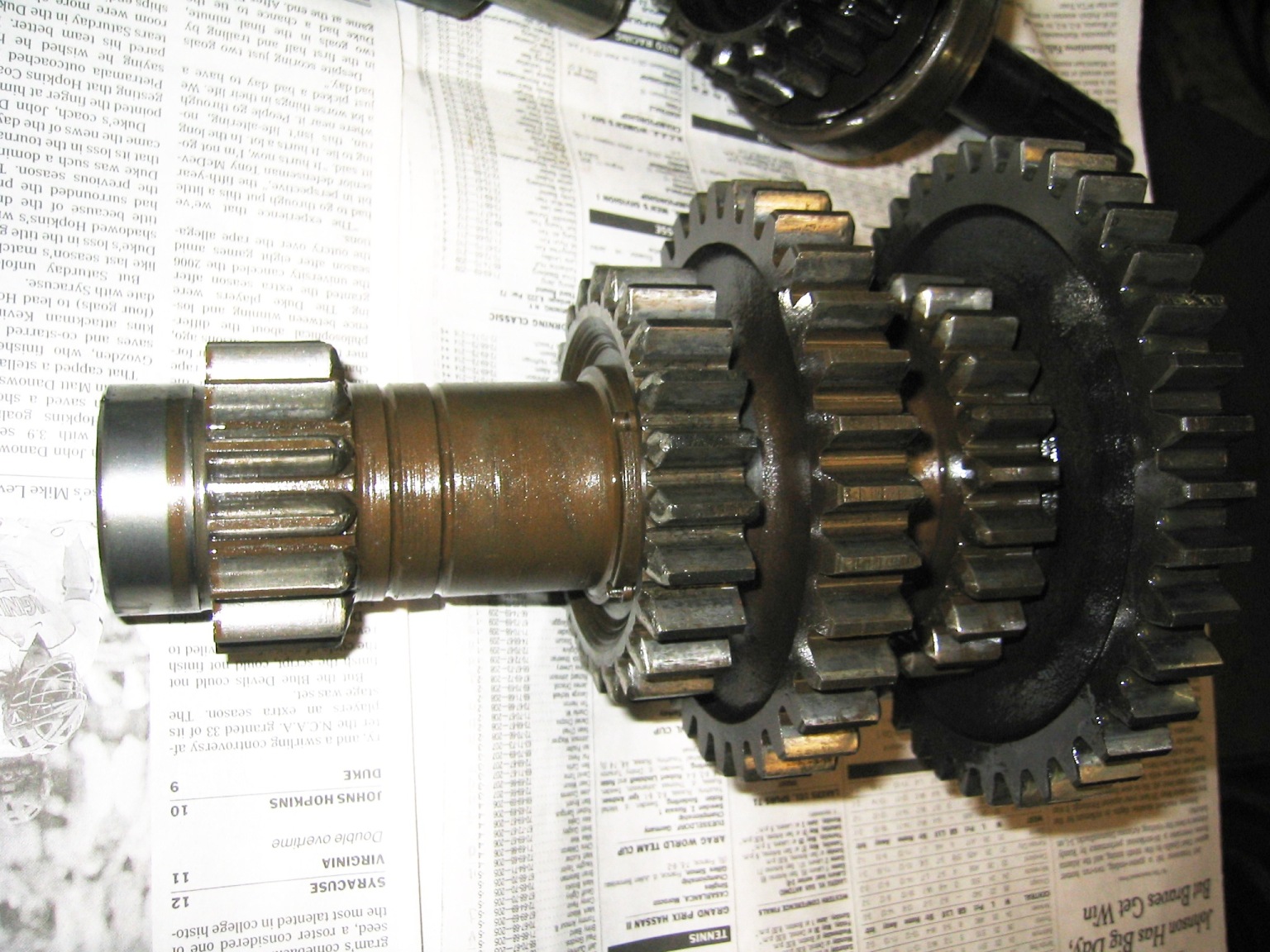

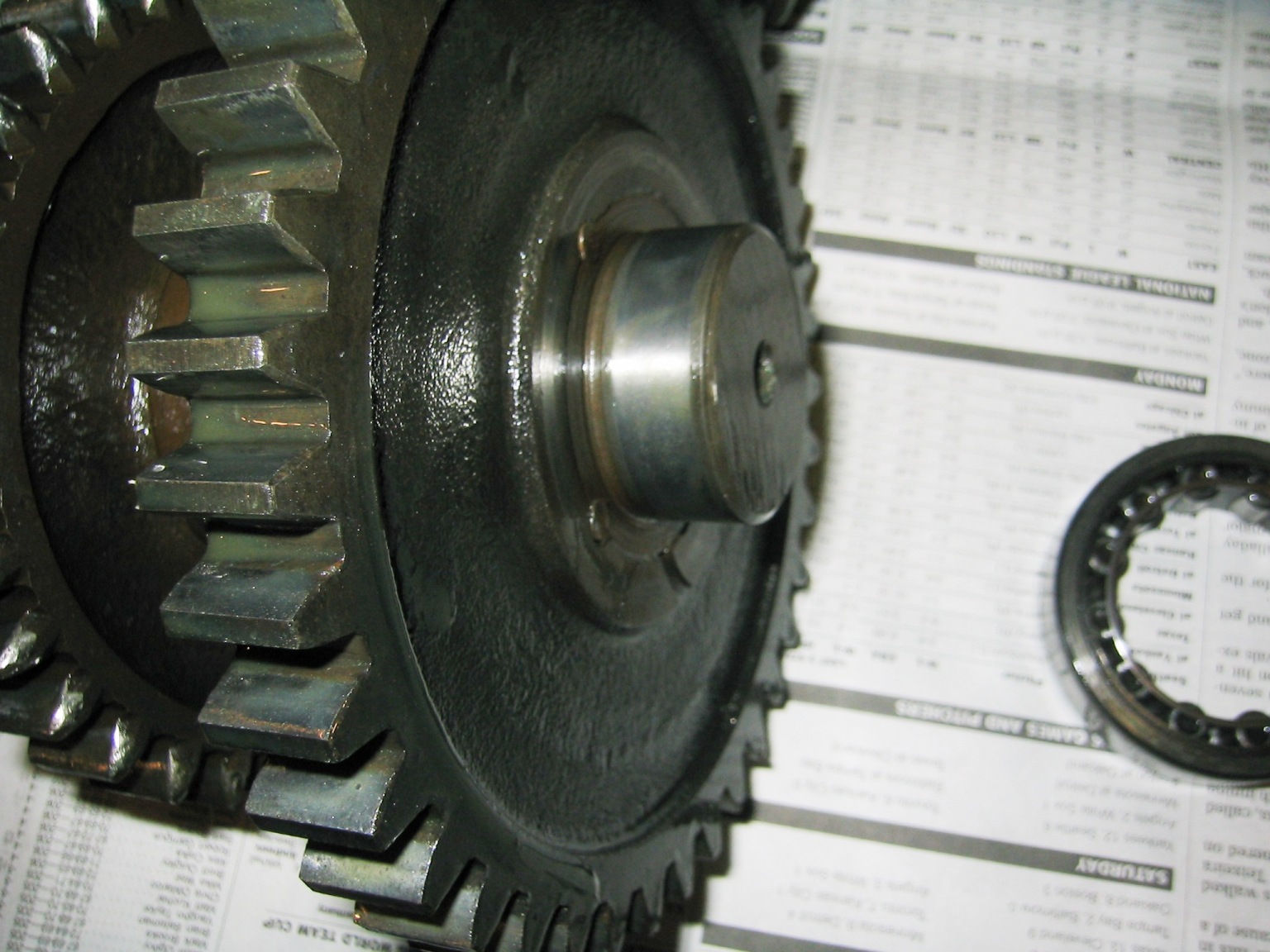

2008 Lower cluster front bearing |

|

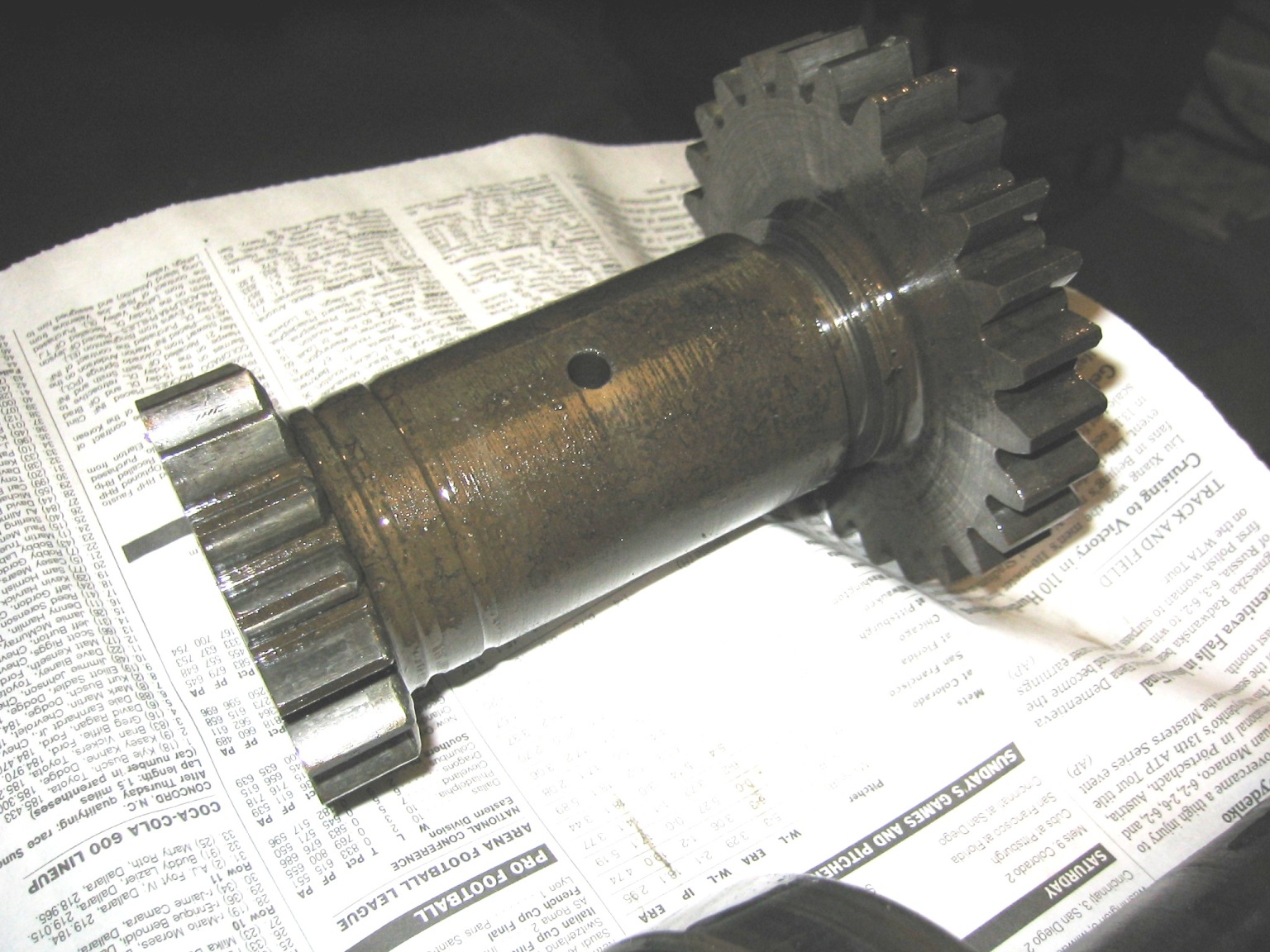

2008 Lower cluster |

|

2008 Lower Cluster rear bearing |

|

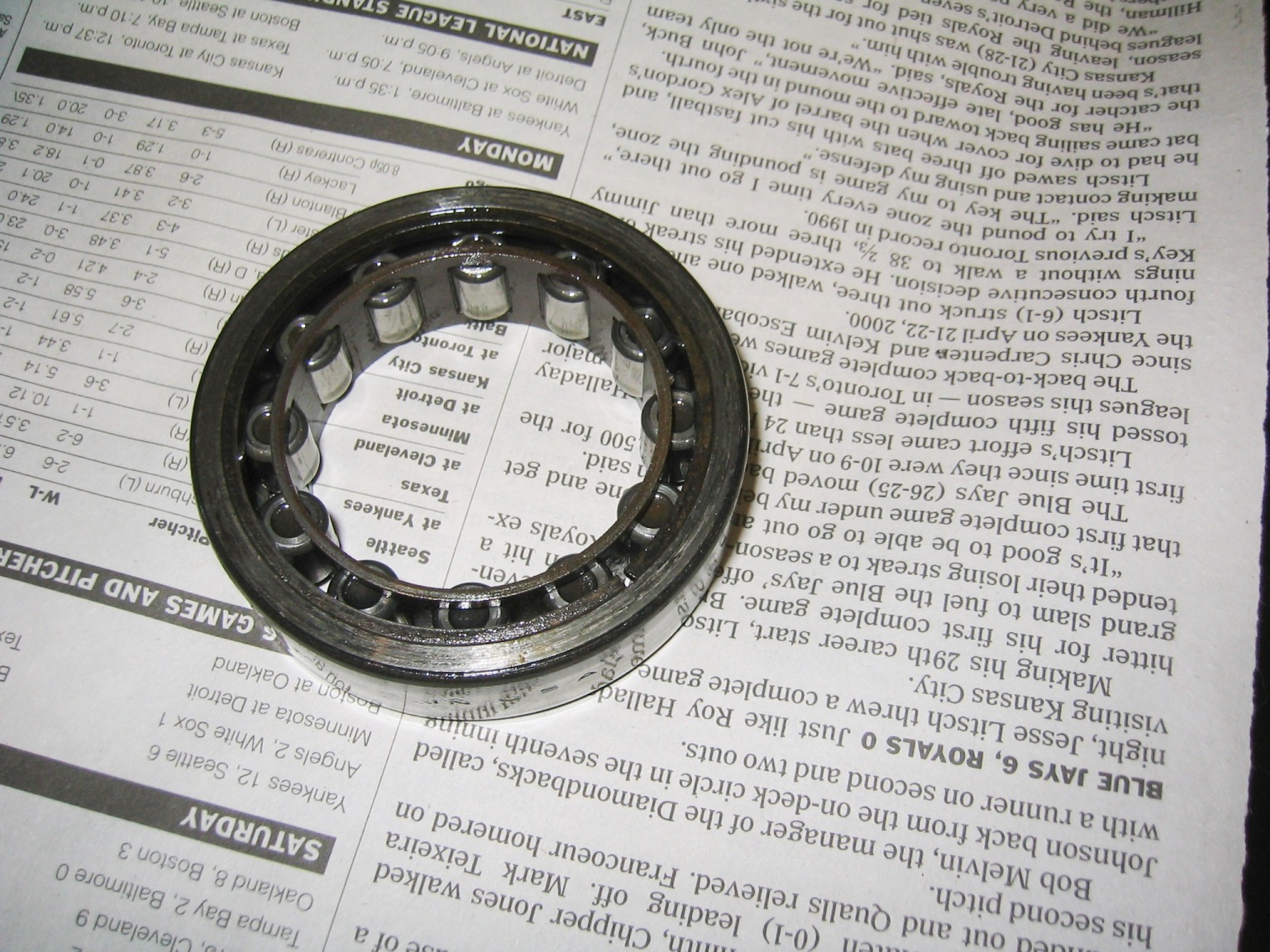

2008 Lower Cluster Rear Bearing |

|

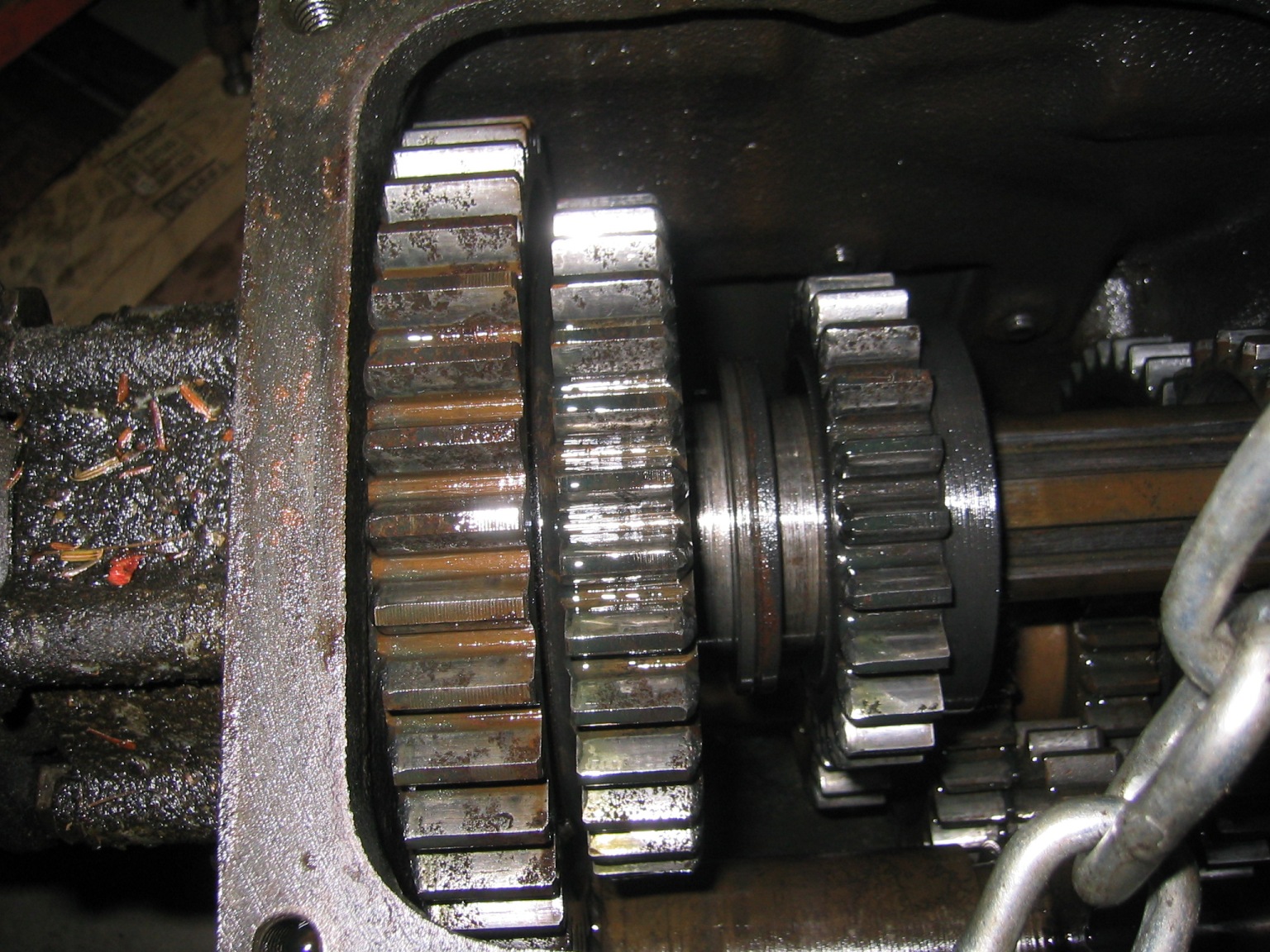

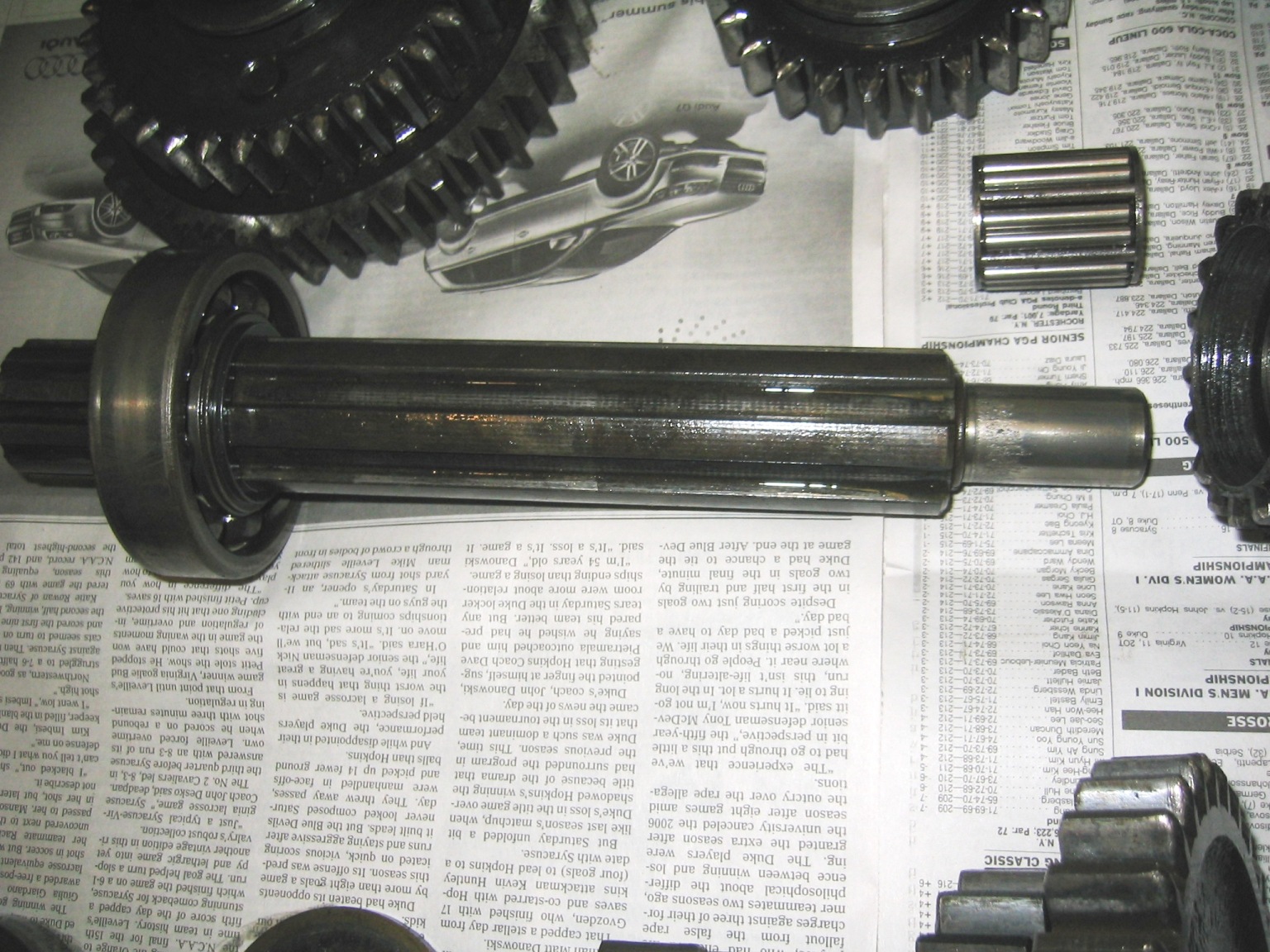

2008 Main Drive Gear # 4.351

These pictures are repeated with different section of the shaft brought

into focus

|

|

2008 Main Drive Gear # 4.351

These pictures are repeated with different section of the shaft brought

into focus

|

|

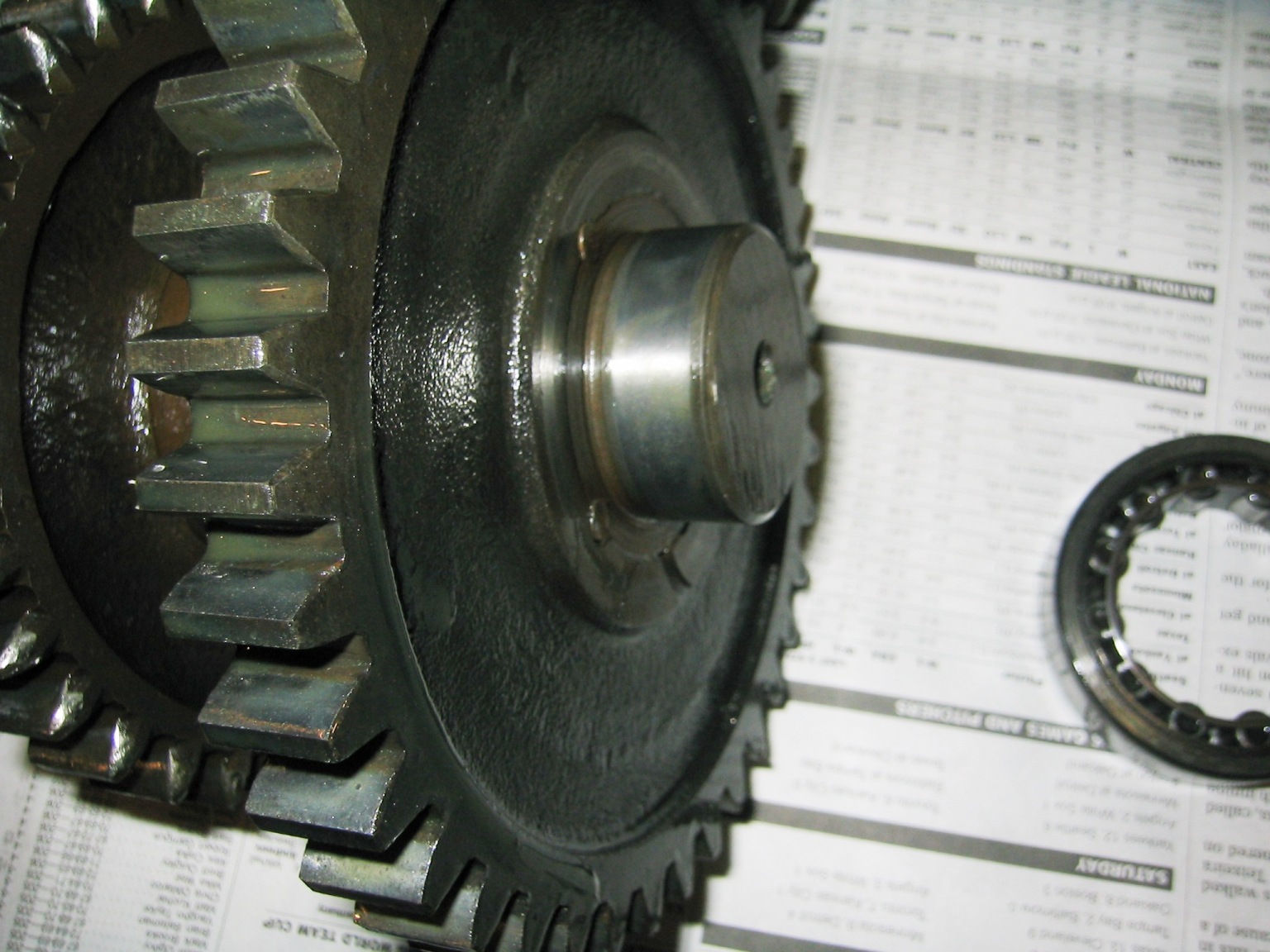

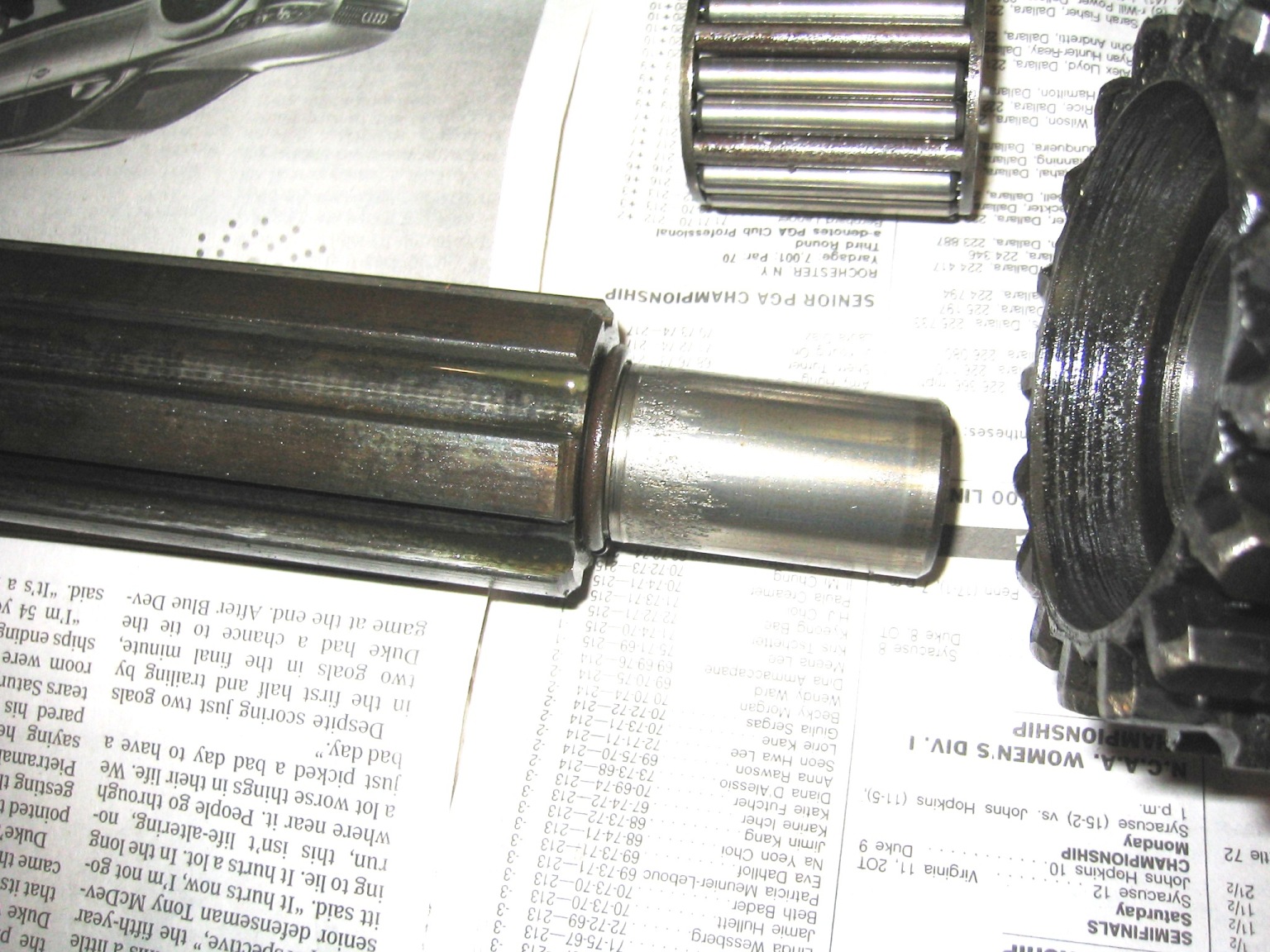

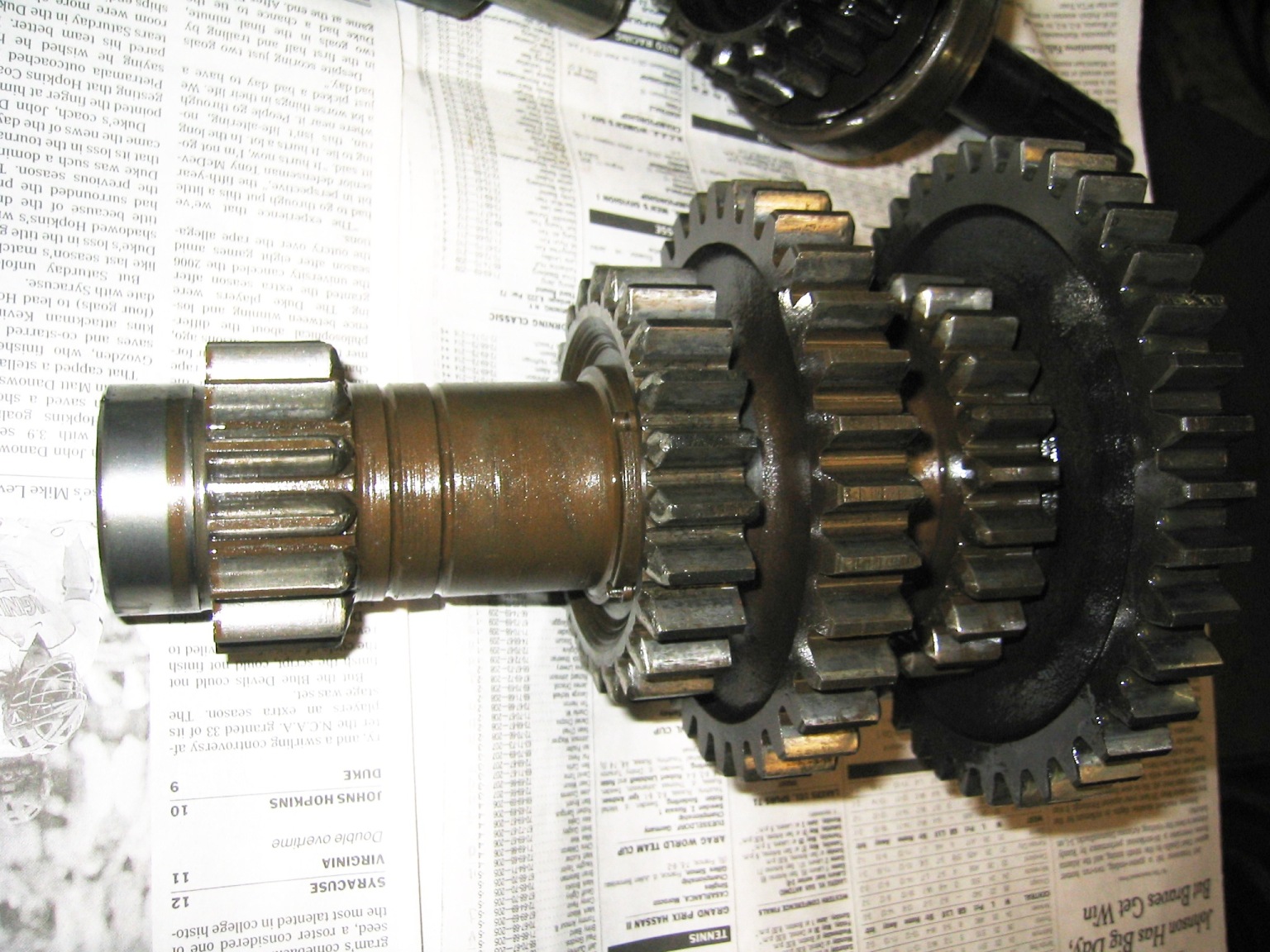

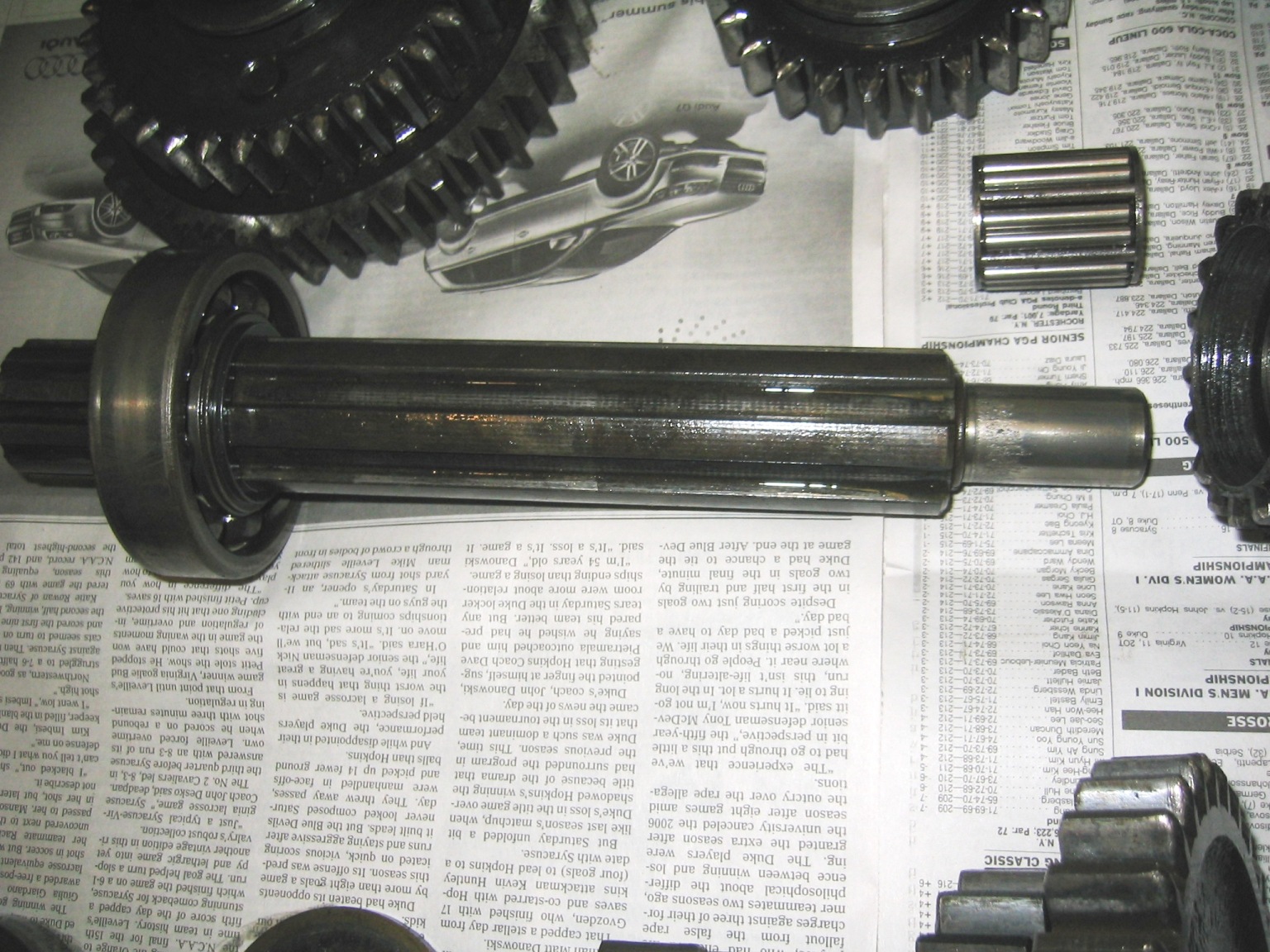

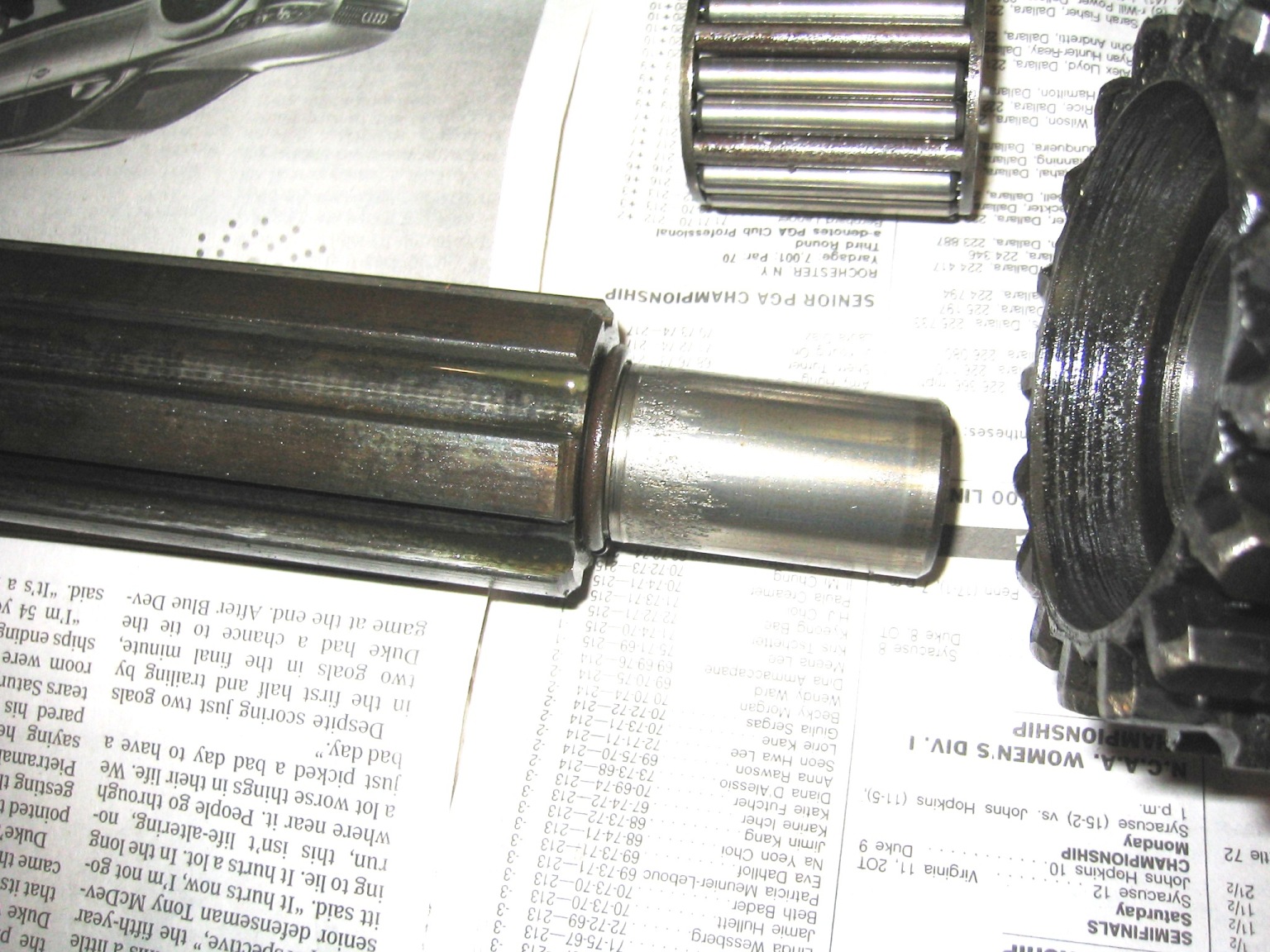

2008 Main Shaft 4.403

Note the bearing surface on the front shaft which rides in the roller

cage bearing inside the Main Drive Gear.

Wear in the area of the first reverse gear and third gear slide gears

is visible but does not seem excessive.

|

|

2008 Main Shaft 4.403

Close up #1

Note the bearing surface on the front shaft which rides in the roller

cage bearing inside the Main Drive Gear.

|

|

2008 Main Shaft 4.403

Close up #2

Note the bearing surface on the front shaft which rides in the roller

cage bearing inside the Main Drive Gear.

|

|

2008 Main Shaft 4.403

Close up #3

Note the bearing surface on the front shaft which rides in the roller

cage bearing inside the Main Drive Gear.

|

|

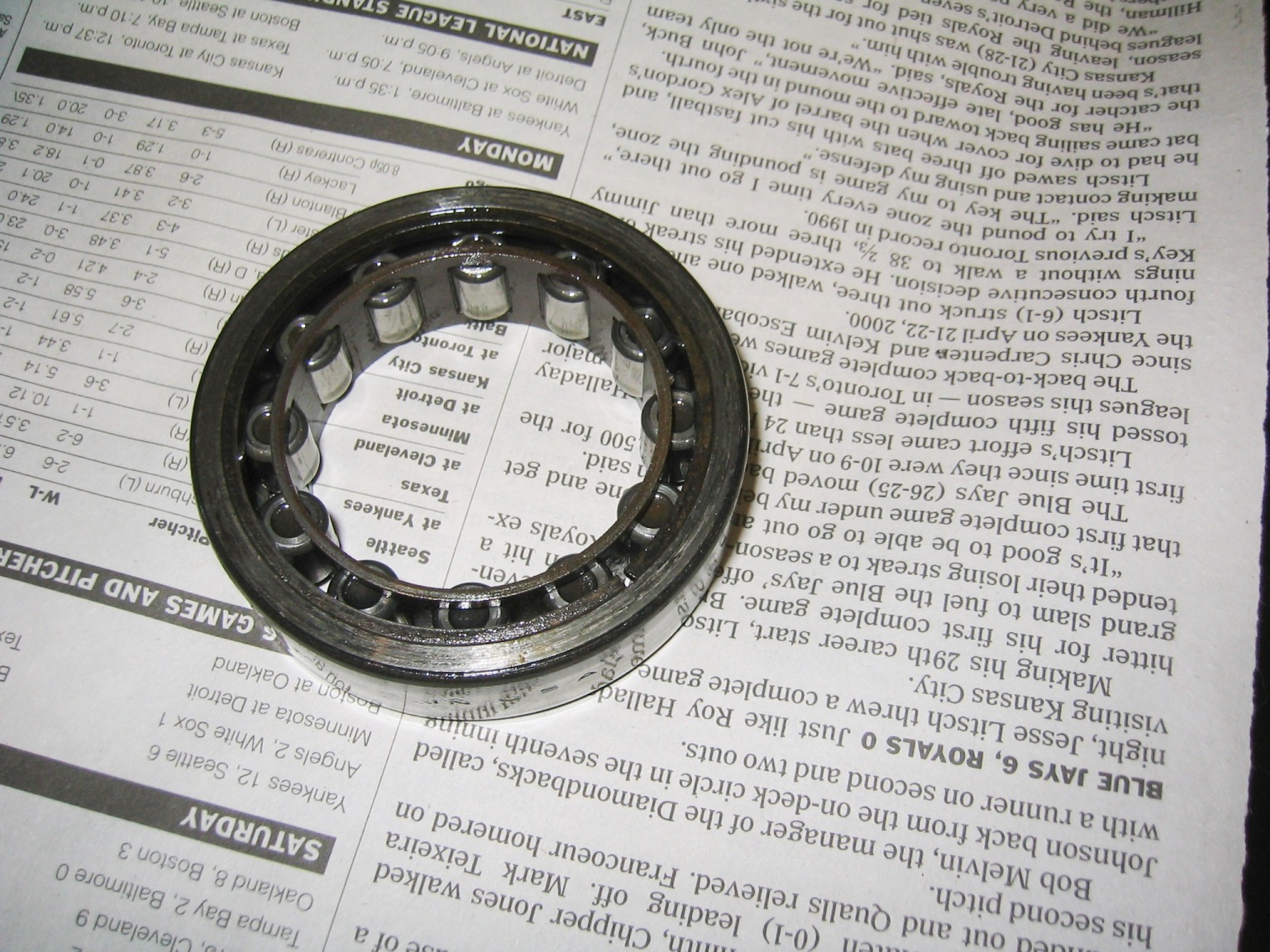

2008 Close up of the Main Shaft Pilot Bearing 4.352

Note the bearing surface on the front shaft which rides in the roller

cage bearing inside the Main Drive Gear.

|

|

2008 First and Reverse Gear 4.417 |

|

2008 High Speed Gear and Counter Shaft Drive

Gear (?) 4.415 |

|

2008 Revers Lower Cluster Idler Gear 4.430 |

|

2008 Revers Lower Cluster Idler Gear 4.430 Bushing 4.431

|

|

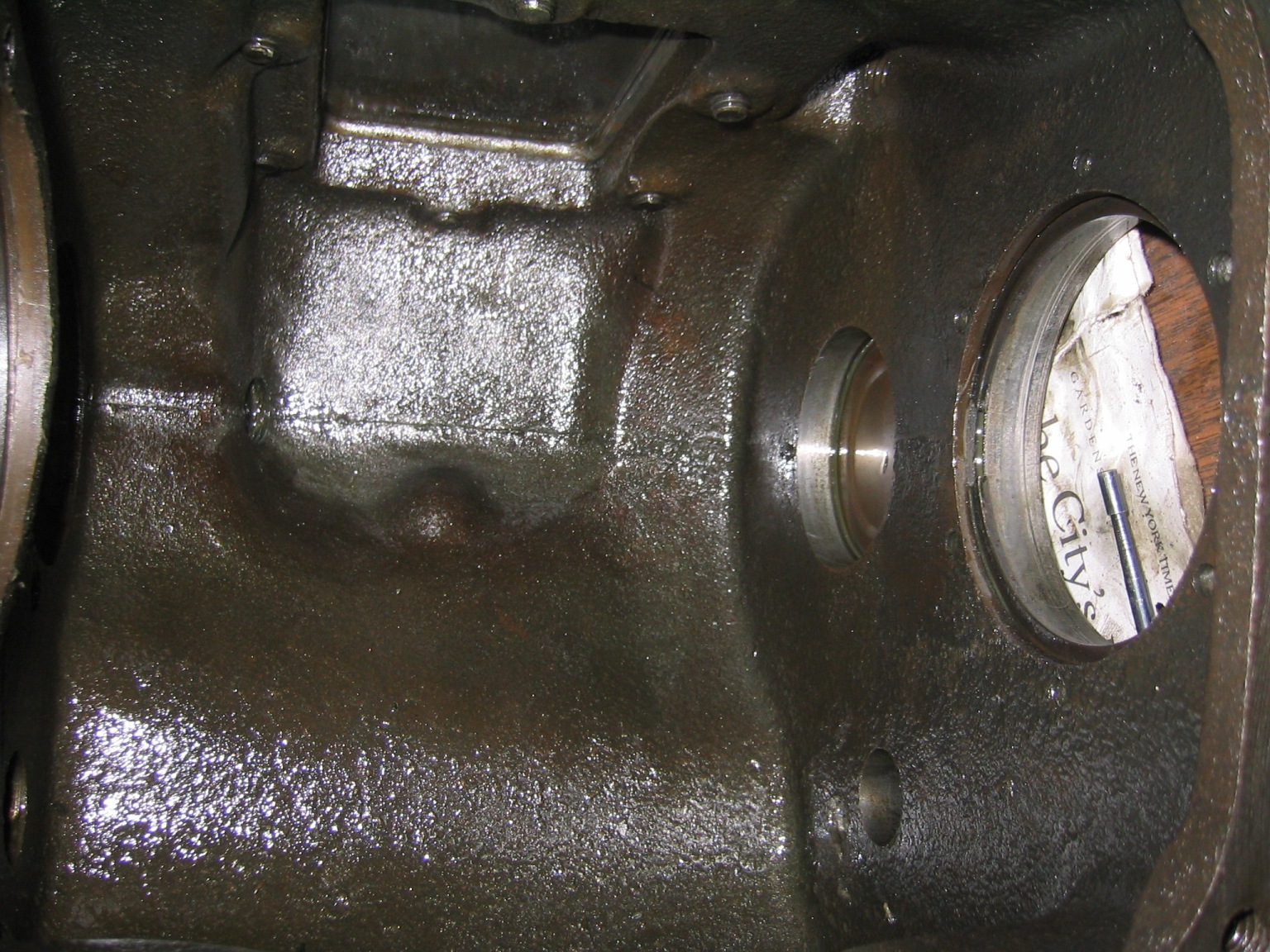

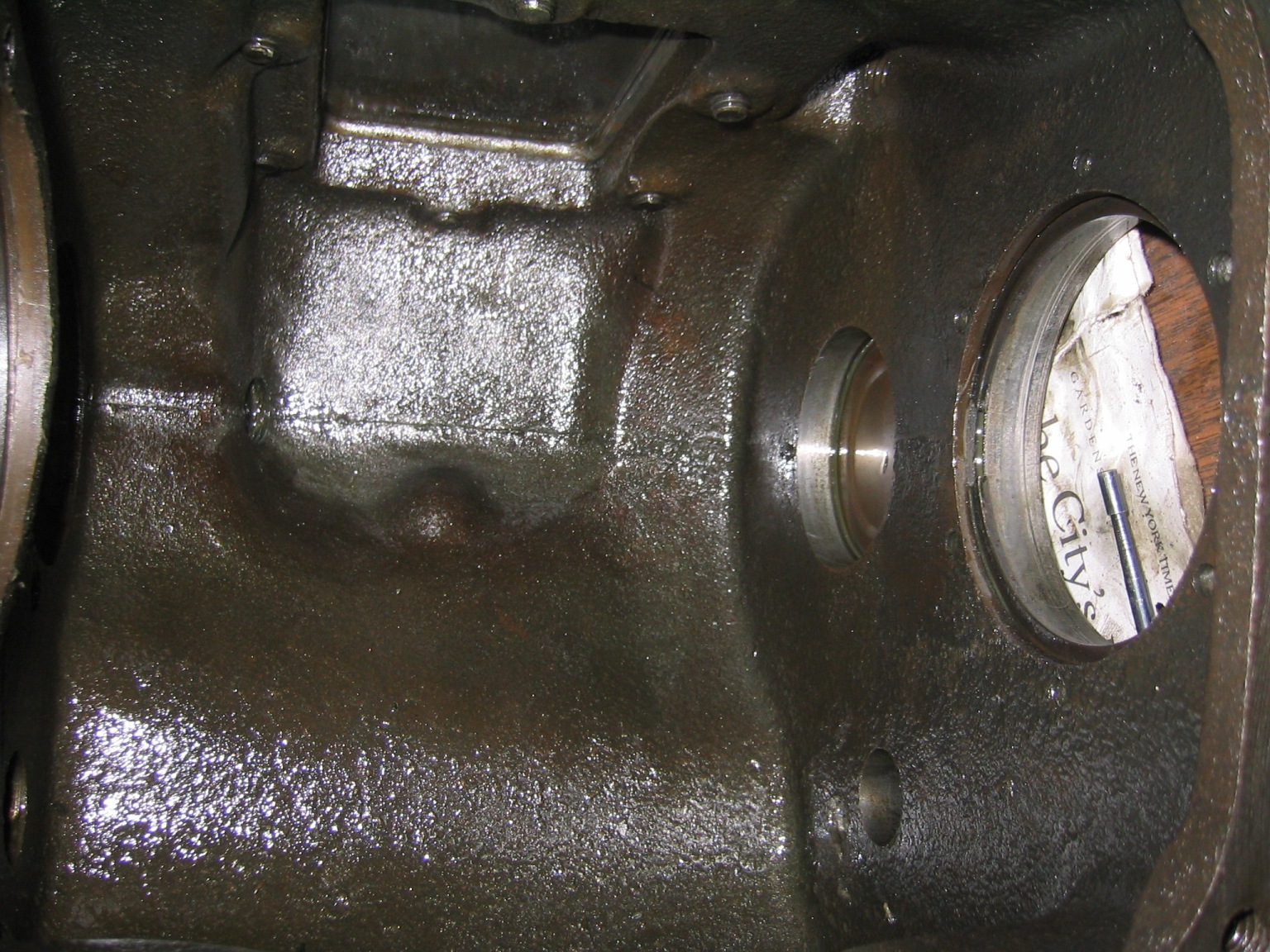

2008 Inside of transmission case |

|

2008 Outside of the transmission case rear |

|

2008 Outside of Counter shaft Bearing 4.22

|

.jpg) |

|

| |

|

| |

|

.jpg)