Chevy 1941 Pattern 12 C60L

Fabricating a New Windscreen

|

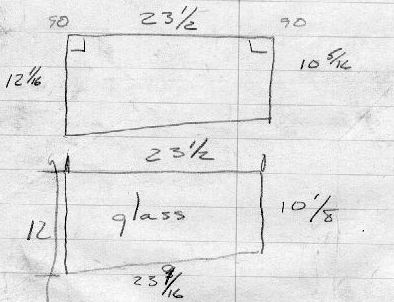

As can be seen in this picture taken January 2002 when I first saw the Pattern 12 it was clear that a lot of sheet metal work was going to be necessary. The back ground photo for this page shows how the truck and been sitting since late 60s. The pictures to the right show the condition of the Windshield or Windscreen. The photos below show the process of making up an entire new Windscreen Frame and Windscreen Mount. I reused what hardware I could which included the clamp nuts and cast brackets and the two window post castings that hold the Mount to the body, and one of these was broken. The Steps were as follows:

|

|

|

|

|

|

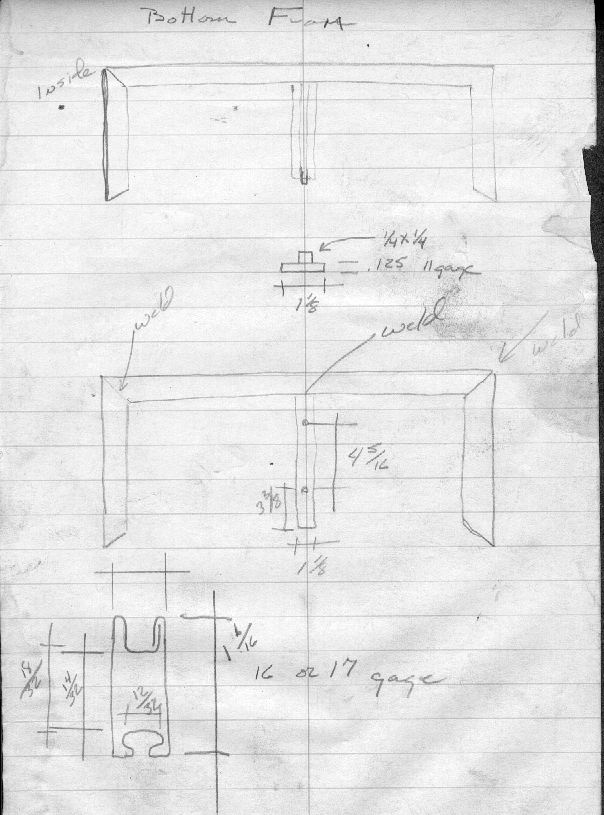

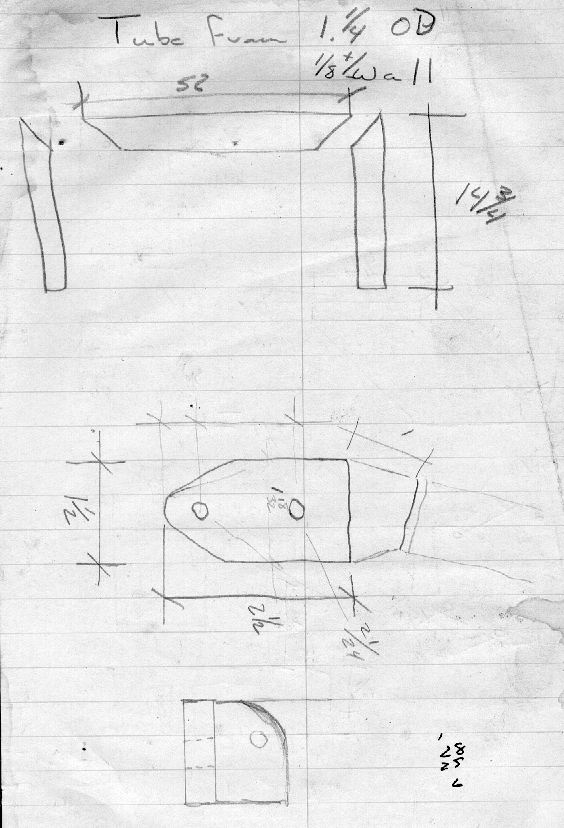

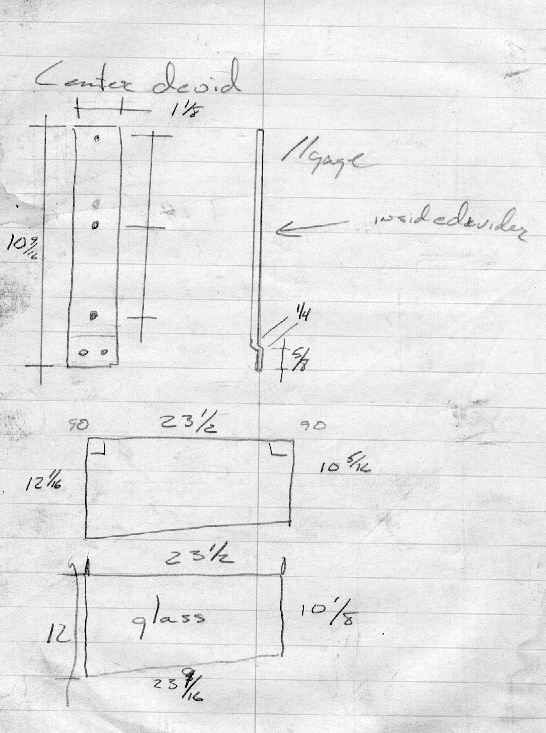

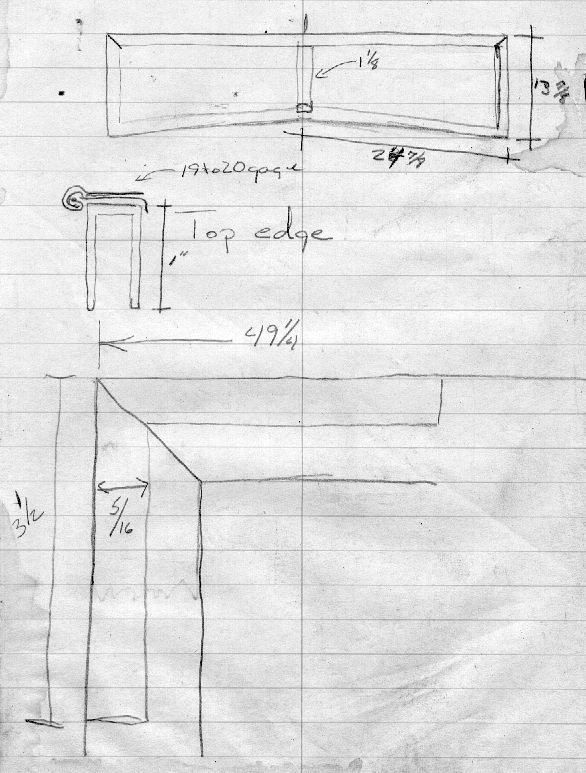

At right you can see the cross section of the (side and bottom) and then on the far right the top edge and the hinge. Once I figure out (actually someone on MLU suggested) that M series window channel might work I got a sample and compared it. Once that looked like it would work I set out to collect enough NOS or very clean window M37 windshield frames. If you can find NOS go that route because I discovered that the bottom channel is particularly subject to rust from the inside out. M37 is also a likely source as there are companies making replacement window frames. In my case I was able to put out the word and several friends in the hobby actually gave me odds and end NOS that they had collected. (I need to take a couple of pictures of the M37 stock to show here) Once stock was found the next step was to make up a jig to hold all the frame parts while welding. Be careful to clamp well and tack weld both side of frame to prevent heat warping before doing the finial weld. Then grind welds smooth. |

|

|

|

|

|

|

|

Here is the end result of the efforts to make a new window frame assembly, this included making up a new pipe frame to hold the windscreen. I have not slid the rubber T gasket in around the sides and bottom, but this is a stock window shop item and can be bought (special ordered) by the roll. Though the pipe frame is drilled to accept windscreen wipers I have not bothered with them with no top mounted wipers that only wipe the outside of the window are going to be of little use. Besides vacuum operated wipers are of minimal value anyway. For years I've used Rain-X on both the inside and out of the windscreens on my other CMPs and thus rarely find a need for the wipers even in hard driving rain. Of course the other two of my CMPs are the Cab 13 with the very effective reverse slope.

|

|

|

Here is what it looks like at 45MPH on interstate highway driving BEAUTY my `42 Pattern 13 C60S, surprisingly I've found that the CMPs (at least the Pattern 13s) are relatively dry even in heavy rains, though I rarely drive with the side curtains in place I find that generally I arrive at the destination drier than those people riding in military Jeeps with full tops even with the side curtains in place. A Jeep in heavy rain with out the side curtain has all the comfort of a cold shower. Now this is not to say that the cab of Pattern 12 or the weather stripping around the windscreens are very water tight, no rather I'd say that the cabs are big enough that the water blowing in around the windscreen has time to fall to the floor before striking the driver or passenger. |