|

|

|

In 25 years of driving my CMPs I have found the engines and trucks to be very reliable. In that they have broken down on me only a very few. Never have the trucks failed to the point of having to be towed home. Break downs include the following :

|

|

Here you can see the

simple design of the transmission.

Four speeds forward one reverse, with straight cut gears which makes double

clutching a requirement. Here you can see the

simple design of the transmission.

Four speeds forward one reverse, with straight cut gears which makes double

clutching a requirement. |

|

|

Top -The valve cover and side panel have just been removed from the engine no cleaning has taken place yet. Note that there is no sign of any sludge or dirt in the engine. This is one of the reasons that I believe the odometer reading of 6314 miles.

Bottom -The valve cover and side panel have just been removed no cleaning has taken place- but water coming from cracks are a bad omen of what is to be found. Again the mileage is low but the 8588.3 miles were hard miles

|

|

|

In the bottom view you can see the detail of the connecting rod scoops or dippers. The engine was in very good condition, compression was good and even once I had check the condition of the inside I replaced the cover gaskets and put it back together to test run extensively. No smoke or oil leakage every thing looked so good I cleaned the outside of the engine in place and painted it. Before cocooning it in plastic and starting on the chassis.

|

|

Layers of paint and cosmoline covered

many parts of the truck. As the cosmoline dried out it peeled the paint

off with it. But the wear on mechanical parts, very little and the very

low mileage on the odometer seemed to match. Layers of paint and cosmoline covered

many parts of the truck. As the cosmoline dried out it peeled the paint

off with it. But the wear on mechanical parts, very little and the very

low mileage on the odometer seemed to match. |

The

nose goes back on once the chassis has been sand blasted and painted and

is going back together. BEAST lends a hand in moving heavy parts around. The

nose goes back on once the chassis has been sand blasted and painted and

is going back together. BEAST lends a hand in moving heavy parts around.

|

|

|

The nose comes back off

and the engine has been pulled. It only took us about 4 hours to have

the engine out and upside The nose comes back off

and the engine has been pulled. It only took us about 4 hours to have

the engine out and upside  down to work on. down to work on. |

Once the crank was removed the cause

of the seal failure was evident the rear main seal surface was pitted.

Why this didn't leak when test run with out load is a mystery. The crank

was sent out and just a trace cut resurfaced it and all of the mains this

with new bearing inserts brought the crank back to spec. Once the crank was removed the cause

of the seal failure was evident the rear main seal surface was pitted.

Why this didn't leak when test run with out load is a mystery. The crank

was sent out and just a trace cut resurfaced it and all of the mains this

with new bearing inserts brought the crank back to spec. |

Three weeks later BEAUTY C60S and BEAST HUP at our summer rally. |

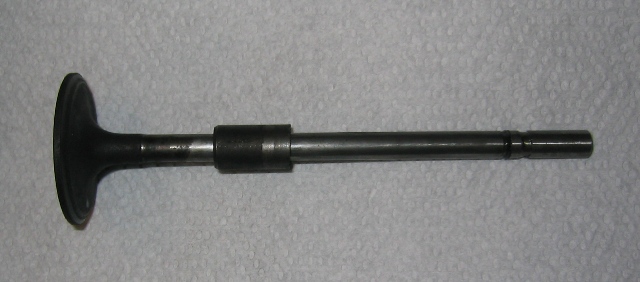

| The next major problem for the C60 came after about 3000 miles and three years. A lose of power returning from an event was the first sign of trouble. The coprate was a burned exhaust valve in number six cylinder. It was interesting that when I pulled the head the cylinder walls had no visible or measurable ring ridge. | The burned valve is a result of the new

unleaded gas from first sign of a leak to a very noticeable lose of power

was only 150 miles all happened in one trip. All of the exhaust valves

showed very noticeable recession. The valve clearance dropped to nearly

"0". |

| Over the ten year Beauty attended a great many events as well as logging some 12,000 miles only one breakdown on the road stopped the truck. That happened on our clubs 2004 Fall Foliage Run. The symptoms- POP BANG WA WA. This all happedn while running along at 50 MPH, down hill, trying to catch the rest of the convoy. After coasting to a stop I had an idea that something in the distributor had let go. Popping the distributor cap off I gave the rotor a twist and it turned. The problem was a broken pin in the distrubutor gear |  |

| After 18 years on the road Beauty came home on the hook for the first time, going out for a Veteran Day event in November while only 3 miles from home, the recently installed freshly rebuilt 261 engine started making noises. First tick, tick, tick like a fan blade just touching the fan shroud. Put the gear box in neutral and coasted to the bottom of the short hill was on and pulled over. Fan OK restarted the engine the noise was louder and the vacuum gage needle was dancing from pin to pin. Not good had the truck towed home and the pictures below tell the story. A intake valve guide had broken and kept the valve from closing all the way. The top of the valve had just barely kissed the top of the piston. But with the valve stuck the valve push rod had been bent. |

|

|

|