The following information relates to a 1941 Pattern 12 Cab C60L CMP information provided is to show the approximate location and routing of the wiring harness.

This is a draft page to get information out quick it will be refined and expanded in the near future.

It can not be too strongly stated that it is important to use cable clamps at many locations along the routing of the harness as is possible. It is also important that other thing such things as brake lines, fuel lines, speedometer cables, and battery cables also be carefully routed and secured. I leaned the hard way when an unsecured speedometer cable shorted out the terminals of the brake light switch on the back of the master cylinder causing the speedometer cable to melt through the insulation of the starter cable the shorting the battery directly along the speedometer cable that then lit up. The results of this was a 2 foot length of the main wiring harness burned up, a burned up battery cable, a destroyed speedometer cable, and a near fire when the heat of all this almost burned through the rubber fuel line.

There should be several more clamps on both on the wireloom harness and on the tar loom just below the hood hinges. Also cable clamps/or friction tape wire treeing needs to be done along many of the single wires to prevent abrasion. The tar loom is not original nor is the terminal block upper right these were added for the turn signals.

In the picture above and at right you may note that a modern circuit breaker has been added next to the voltage regulator. This was done after the fire.

Note that there are bent metal tabs designed to hold the wiring harness in place (these were missing in some locations and had to be added back. In the picture at right the tabs on the radiator have not been used for the wiring and it is unclear if these were for the wiring or for the overflow pipes for the radiator. The harness on my truck when I got it was friction taped in the cross bar behind the radiator.

Blow you can see the routing of the wire down to the generator and to the horn, on the Ford of course the horn is mounted lower down on the left side of the grill.

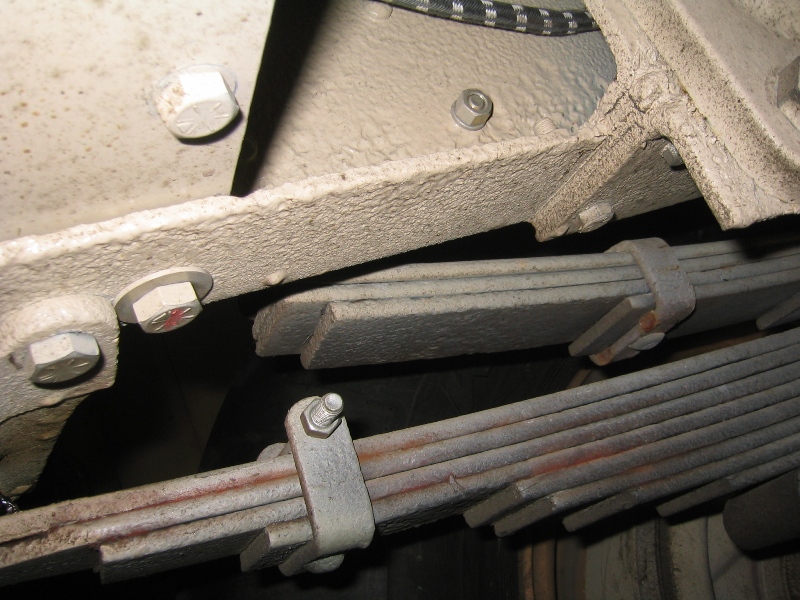

There should also be cable clamp on the vertical harness coming down along side the radiator using the radiator mounting bolts. Once down to the frame the harness goes behind the first frame cross member and along the lower frame rail (see picture below left). On the Chevy there are a number of 1/4 inch holes running along this section of the frame which are used to secure the harness cable clamps.

In the picture below you can see two of these bolt locations these are also used to clamp the steel fuel line. I need to re-examine which should be on the inside (I believe the harness should behind the fuel line with the clams providing about and inch of separation

The wire connections shown in the picture below are not in the typical of CMP harness location. These were added to replace the 2 foot section that was burned.

My fuel line plumbing is temporary until I finish making new fuel tanks then the rubber and copper will be replaced with steel fuel line accept for the short flex line that connects the fuel line to the fuel pump.

In this picture you can see the correct location for the connections between the front harness and the rear harness (this allowed the same front harnesses to be used on all Chevy CMP trucks regardless of wheel base) the rear harness is made up either for the 101, 134, or 156 inch wheel base. This connection location is in the frame cross member which holds the transfer case, and because of the extra bracing is a well protected if oil location. The two connector not connected are the two leads to the fuel tank sender units.

Here is the wiring harness and brake line emerging from the back of the transfer case cross member the rubber hose around the harness is a temporary expedient until I can find or make the proper grommets for each of the frame holes that the harness and brakelines pass through.

Disassemble of the Ignition Switch Video of assembly & disassembly